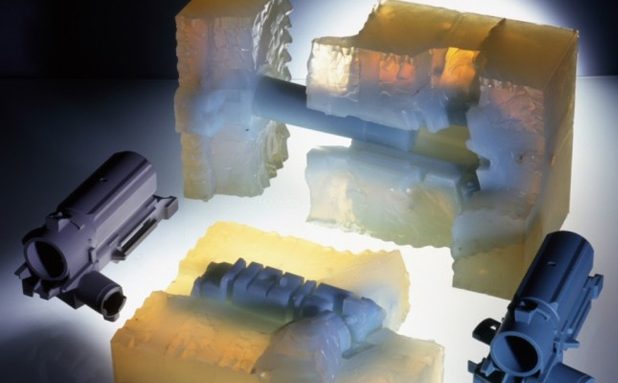

Sand Castings vs Investment Castings. Sand castings typically hold a tolerance plus or minus .020 up to 10 per inch then add ±.001/in after that depending on the pattern equipment used and whether they use no bake sand or green sand. Investment or lost wax castings will generally hold a tolerance of plus or minus 0.005 per inch. Investment casting also have a much better surface finish typically a 125. micro finish. While a sand casting is typically 200 to 250 RMS.

The investment process can also produce more intricate parts and finished internal surfaces with complex coring possible reducing some or all machining cost. The investment process can also produce a wall thickness as low as 0.060 to 0.090 and some holes can be cast depending on size and tolerances. The dies used in the investment process are typically much less than those used in the die casting or forging process and will last forever because they produce wax molds. We do not pour any Iron in the investment process.

Contact Us if you have questions about Sand Castings vs Investment Castings.

Recent Comments